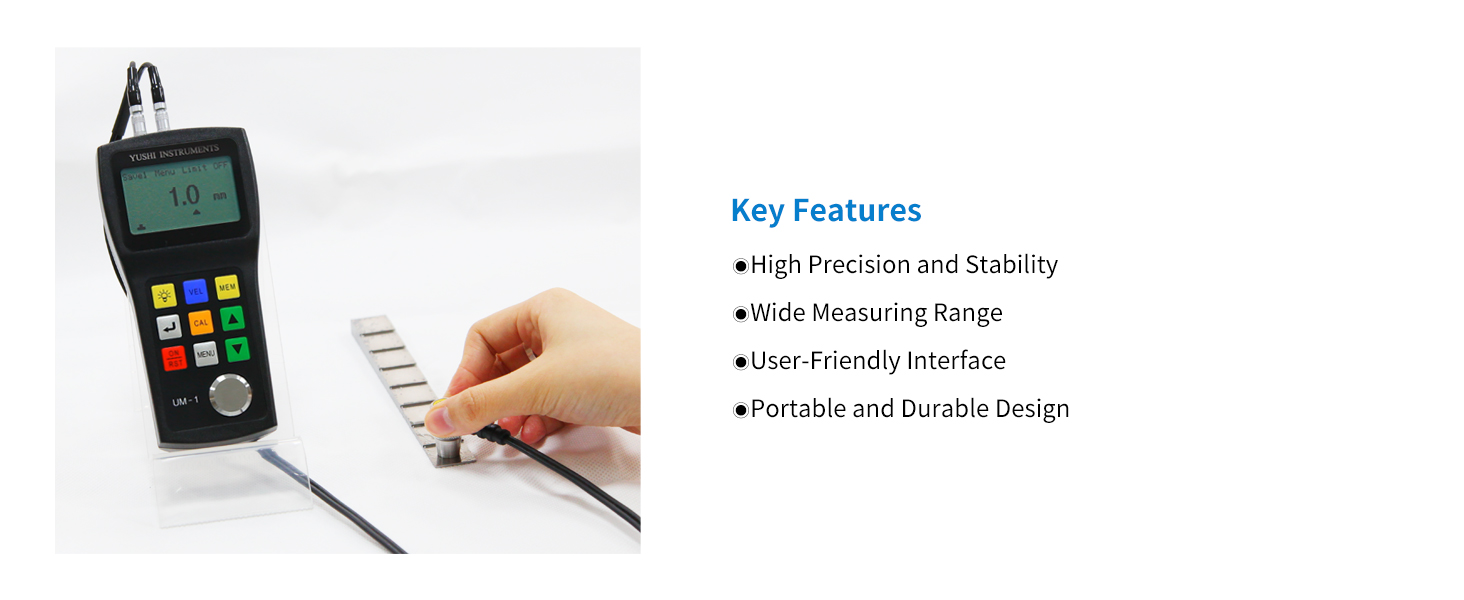

YUSHI UM-1 Series Ultrasonic Thickness Gauge

Reliable, Portable, and Coating-Friendly

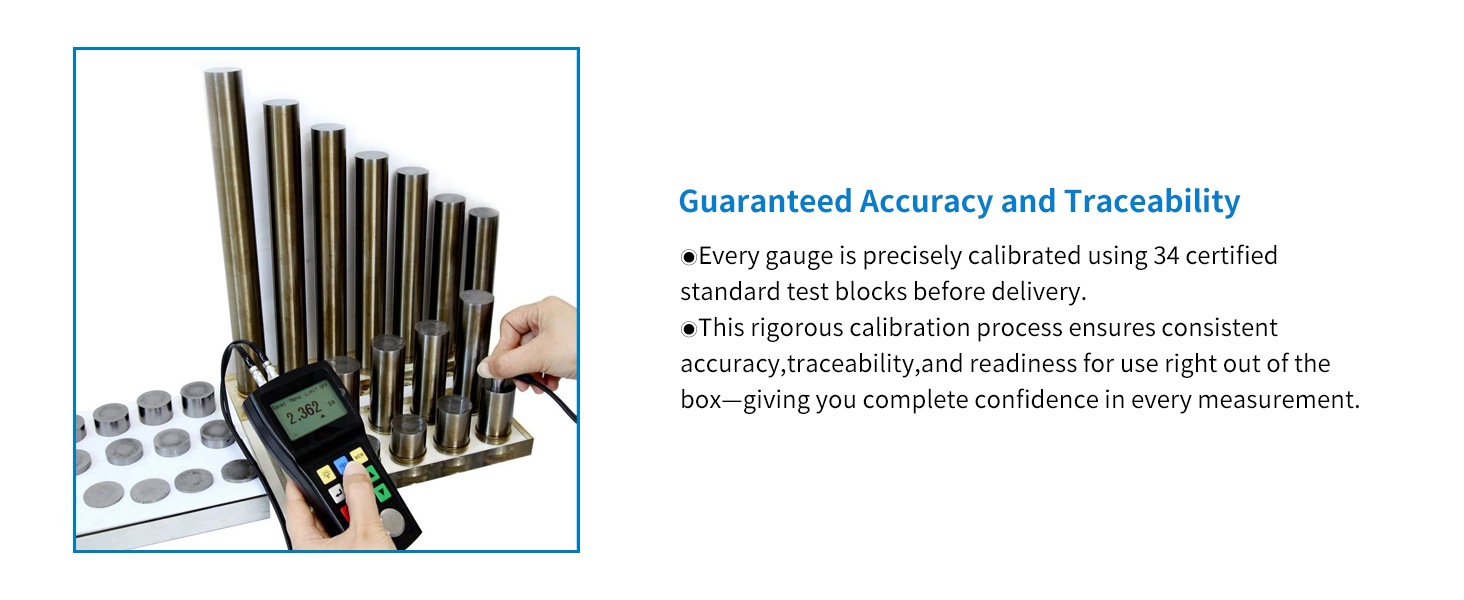

The YUSHI UM-1 Series is a hand-held ultrasonic thickness gauge designed for quick, reliable, and non-destructive thickness measurements on a variety of materials. With advanced signal processing and stable performance, the UM-1 series is ideal for manufacturing, quality control, and corrosion inspection.

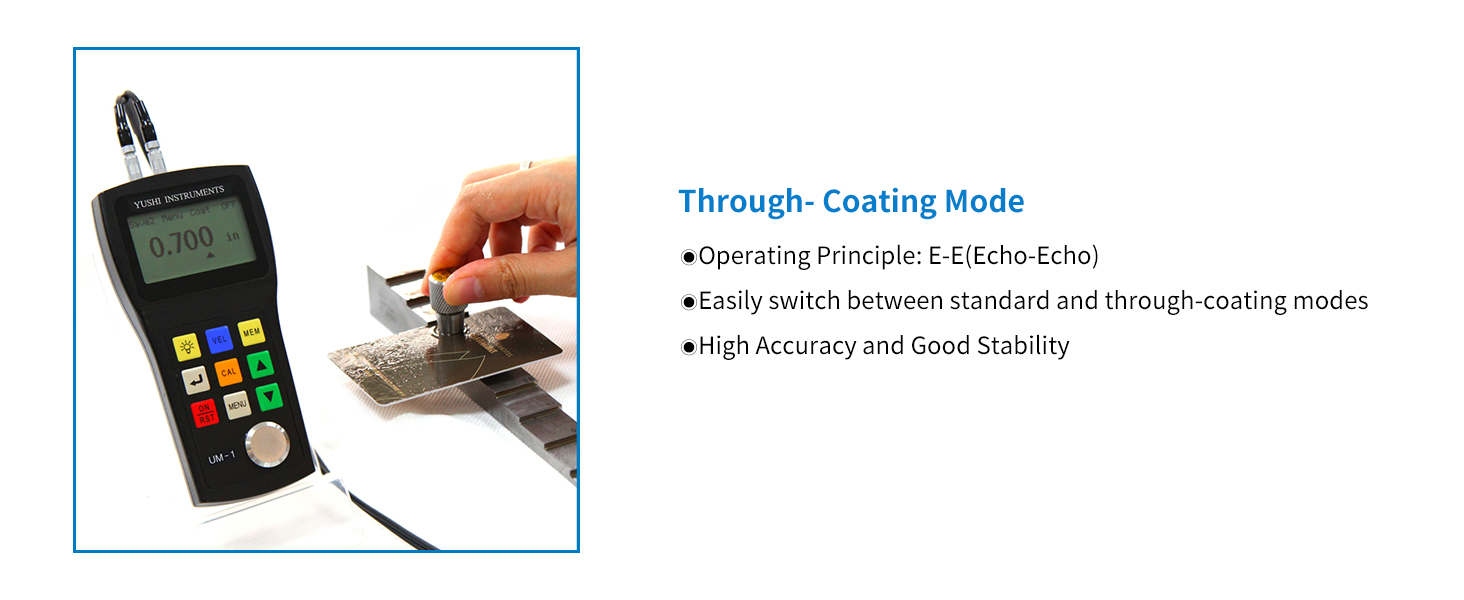

For painted or coated surfaces, the UM-1D model supports through-coating measurement, allowing users to get accurate base material readings without removing paint or coatings.

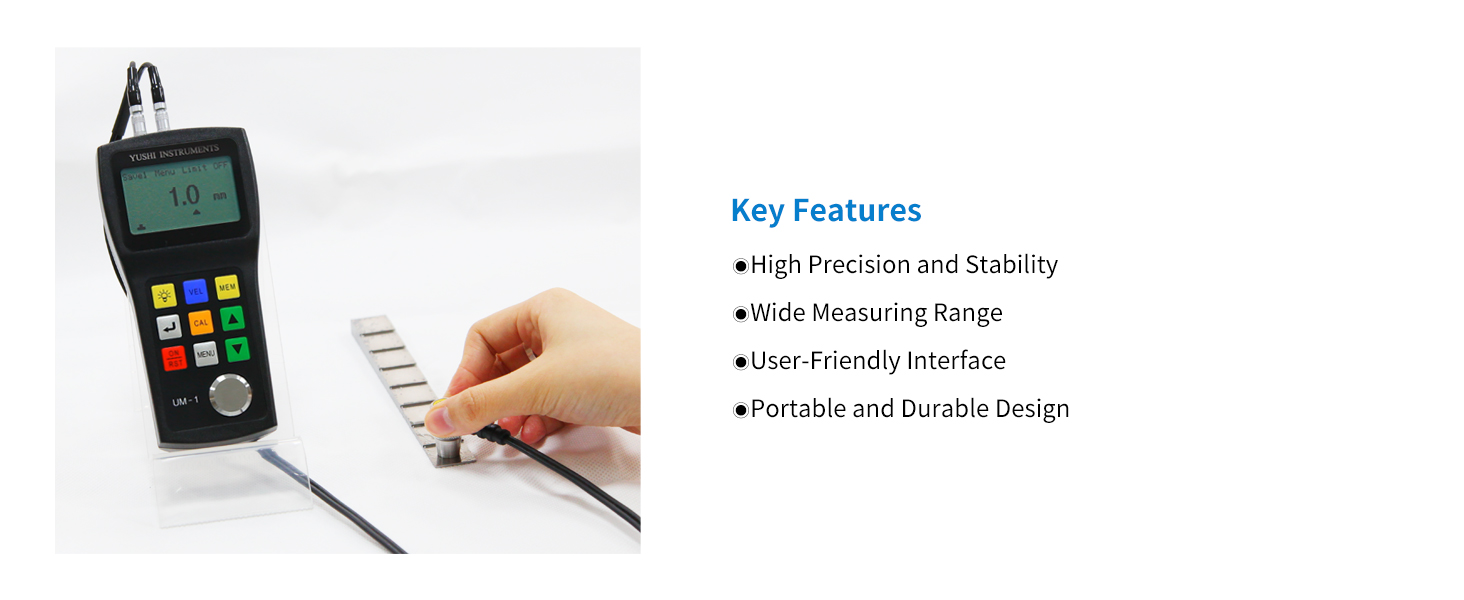

Key Features

Measurement Range:

Accuracy: ±0.1 mm

Automatic V-Path Correction for curved surfaces

Warning Alarm when thickness exceeds preset limits

Data Storage: Stores up to 500 readings in 5 groups

USB or RS-232 Interface (optional) for PC connection

Long Battery Life: Up to 200 hours (without backlight)

Languages: English / Chinese

Backlit LCD Display for clear readings in low light

Applications

Corrosion and erosion inspection in metal pipelines or structures

Quality control in manufacturing processes

Measurement of painted or coated components

Testing of small tubes, cast iron, or high-temperature surfaces (with optional probes)

Technical Summary

Resolution: 0.1 mm / 0.01 in

Material Velocity Range: 1000 – 9999 m/s

Display: 128×64 LCD with EL backlight

Operating Temp: -10°C to +50°C

Size / Weight: 149 × 73 × 32 mm / 210 g

Need accurate thickness results in a compact and user-friendly device?

Choose the YUSHI UM-1 Series — economical, proven, practical, and powerful.

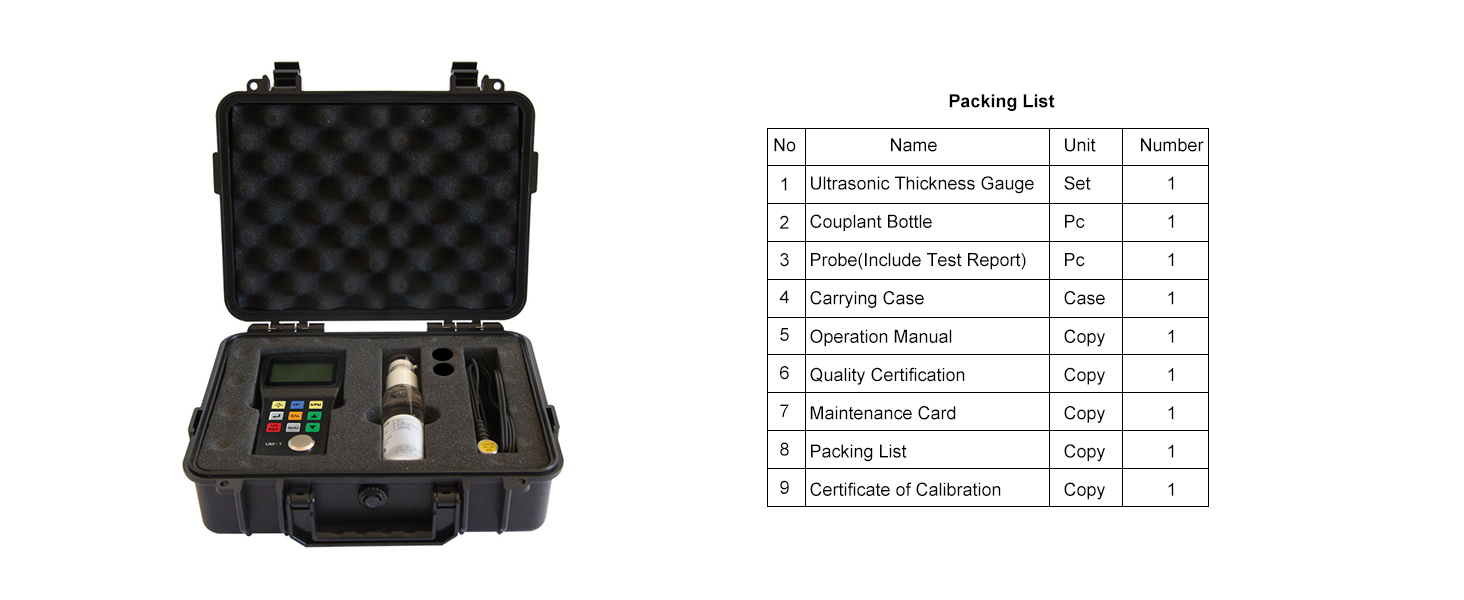

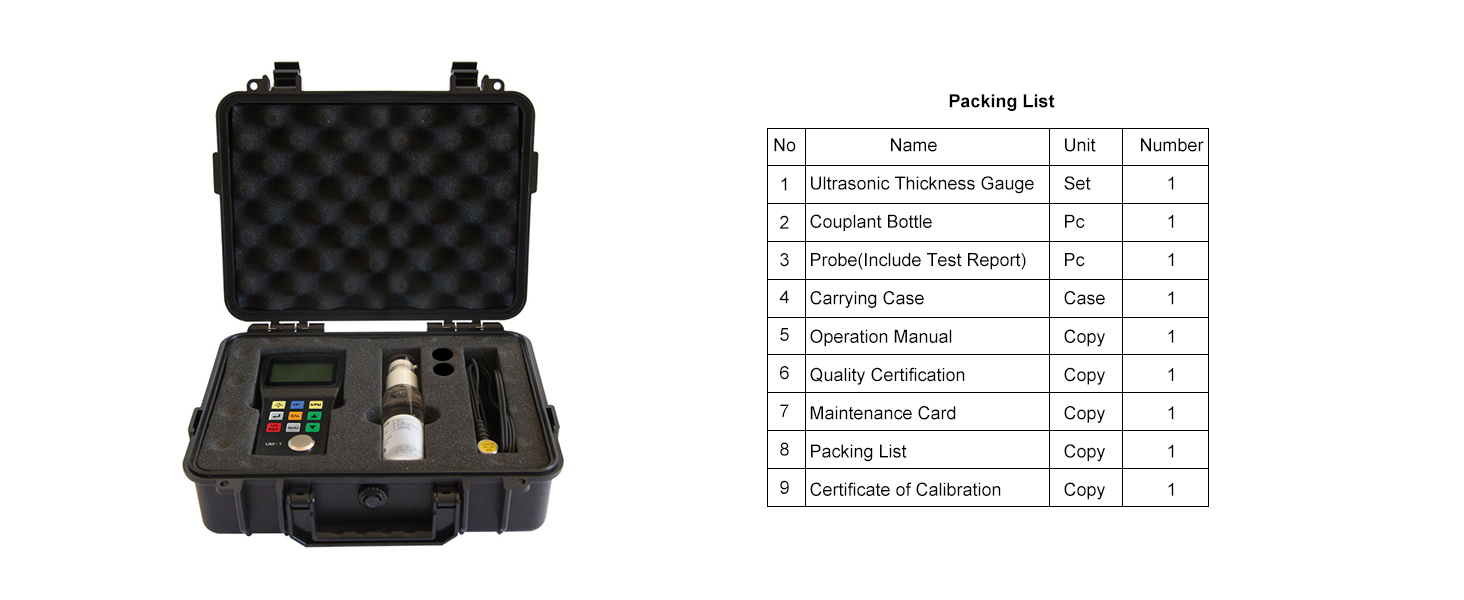

Technical Parameters

Display Type

| 128×64 dot-matrix LCD screen with EL backlight |

| Operating Principle | P-E (pulse-echo) , E-E (echo-echo) with dual-crystal probes (Only UM-1D) |

| Measuring Range | 0.8mm to 300mm, depending on material and probes

|

| Measuring Range In Thru Coating Mode | 3mm-20mm with PT-08 probe(Only UM-1D)

|

| Measuring Limits of Tube (Steel) | Φ20mm×3.0mm(PT-08 probe) |

Measuring Error

| Low limit to 10mm: ±0.1mm 10mm to high limit: ± (1%H+0.1) mm Note: H is the actual thickness of the testing material |

| Display Resolution | 0.1mm,0.001 inch |

| Units | Inch or Millimeter |

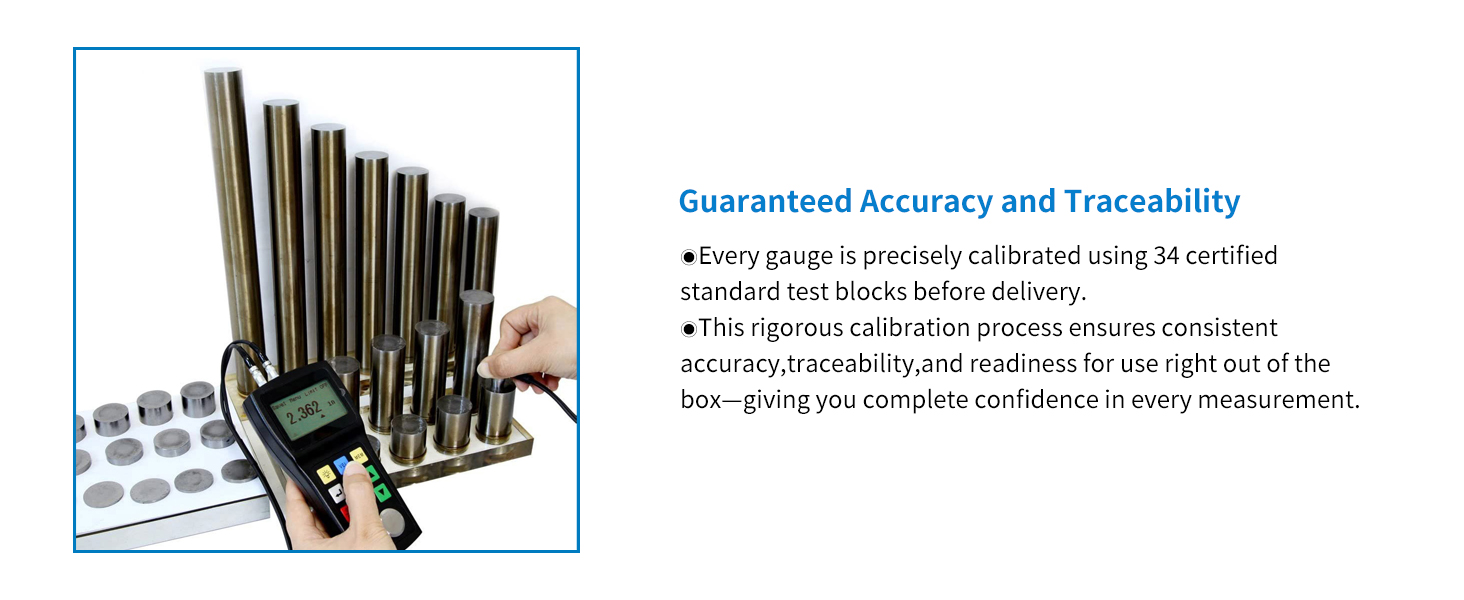

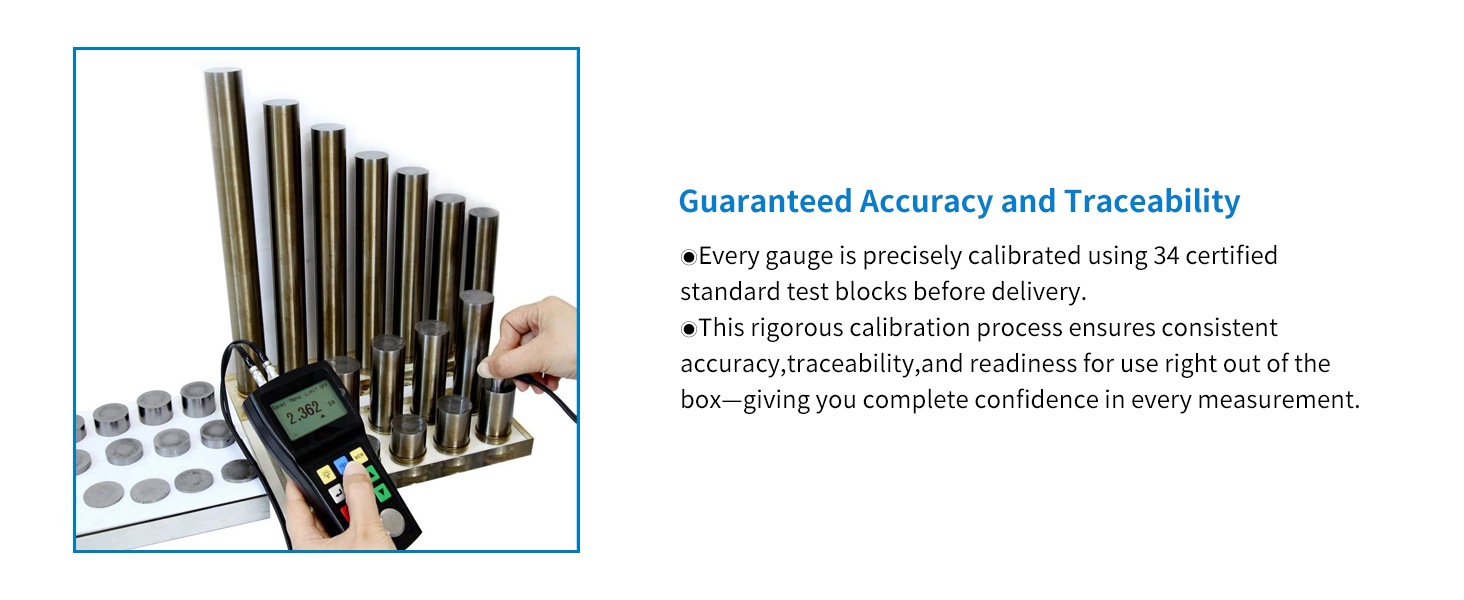

Calibration Method

| Zero calibration,Two-point calibration |

V-Path Correction

| Automatic |

| Update Rate | 4Hz |

| Material Velocity Range | 1000 ~ 9999 m/s (0.0394 to 0.3937in/us)

|

| Memory Function | 5 arrays are divided to store 500 thickness values |

| Languages | English and Chinese |

| Communication Port | USB port or Serial RS 232 port (Optional) |

| Operating Time | Up to 200 hours with alkaline batteries (without backlight) |

| Instrument Shut-off | AUTO OFF after 5 minutes of inactivity |

UM-1 vs UM-1D Comparison Chart

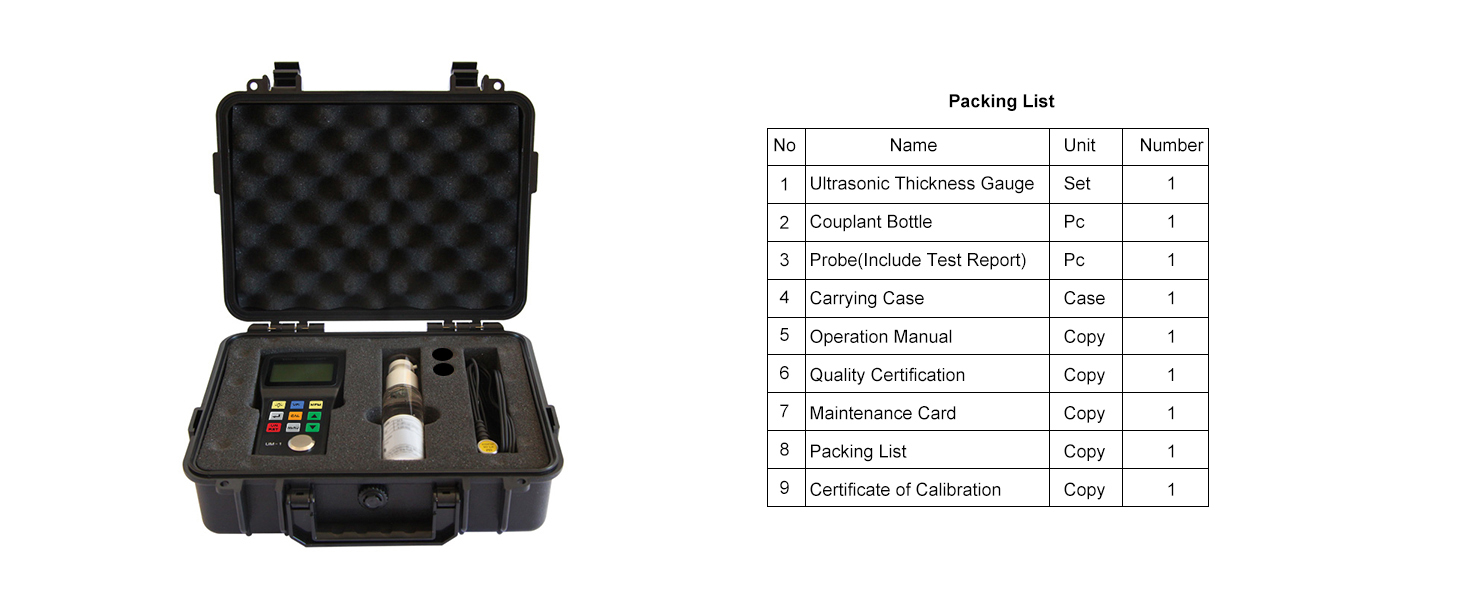

| Model | UM-1 | UM-1D |

| Operating Principle | Pulse-Echo | Pulse-Echo Echo-Echo |

Measuring Range in standard mode | 0.8mm-300mm/0.03-11.81 in.(Depend on material and probe) |

Measuring Range in Thru Coating Mode |

/ |

3-20mm (0.12-0.79 in.)

|

| Measuring Resolution | 0.1mm / 0.01inch |

| Probe Compensating Line | 1 built-in probe compensating line |

| Data Logger | 500 readings can be stored in 5 groups |