Testing Case 1: Through-Thick Coating Measurement

Testing Case 2: Ultrathin Material Measurement

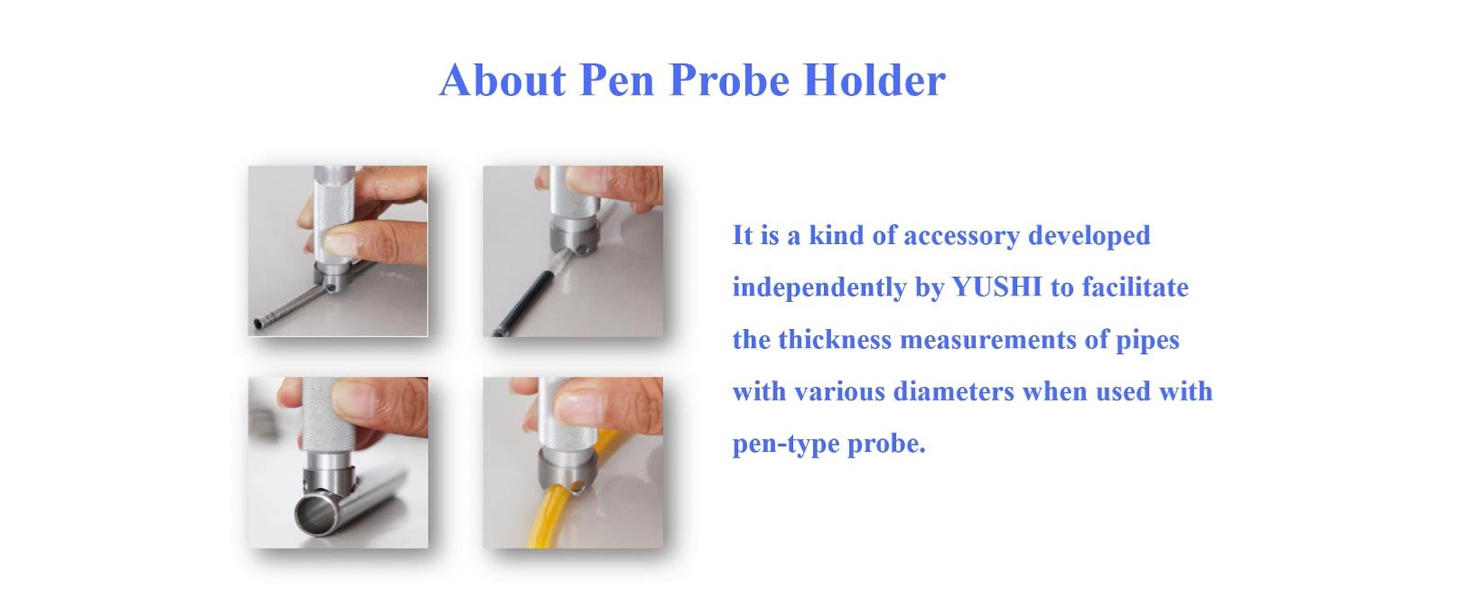

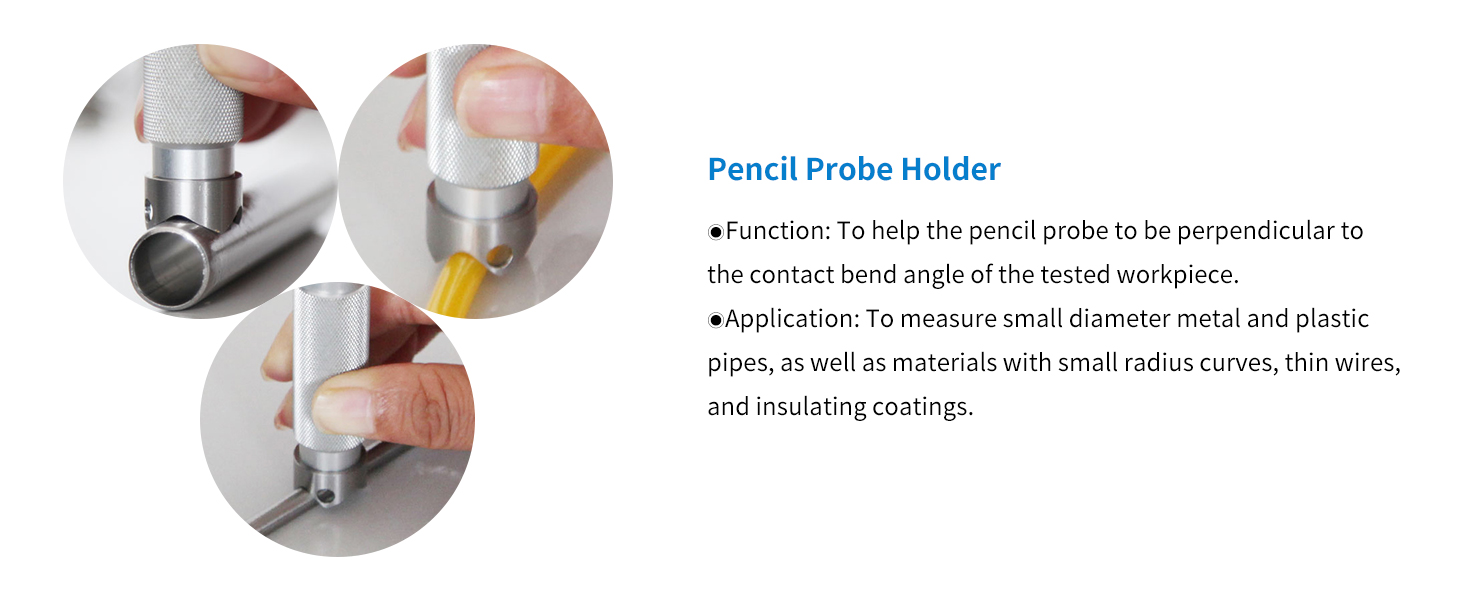

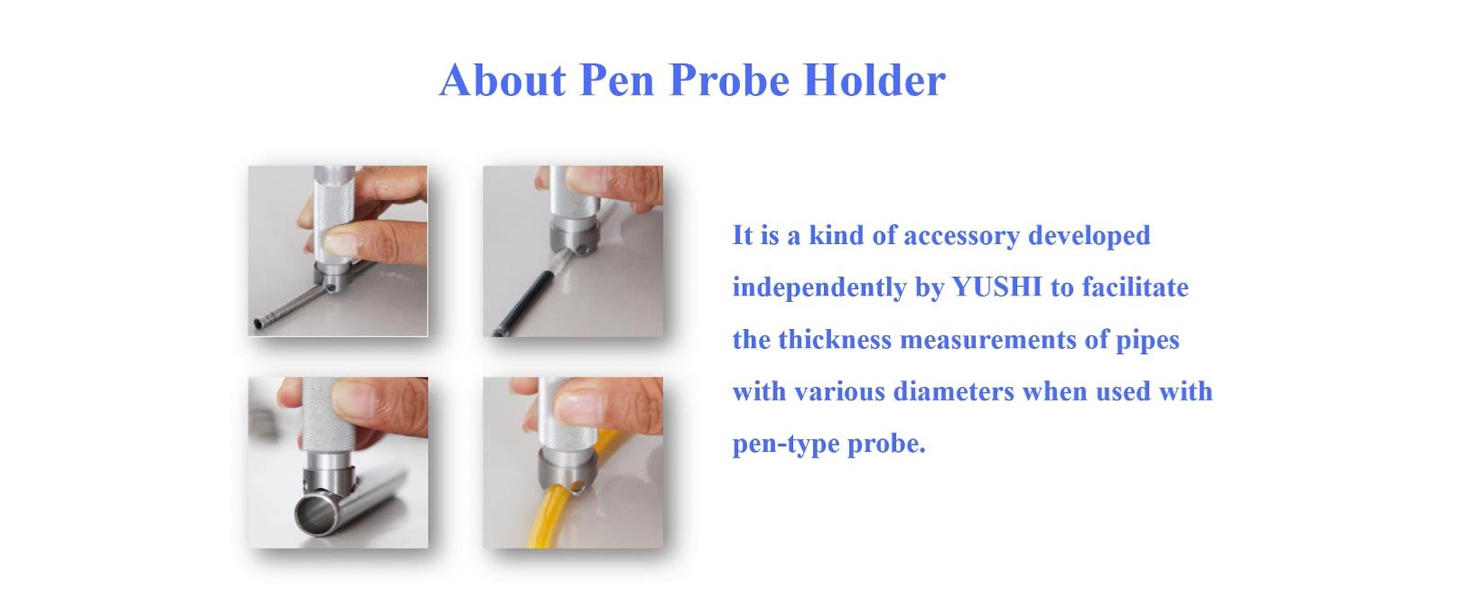

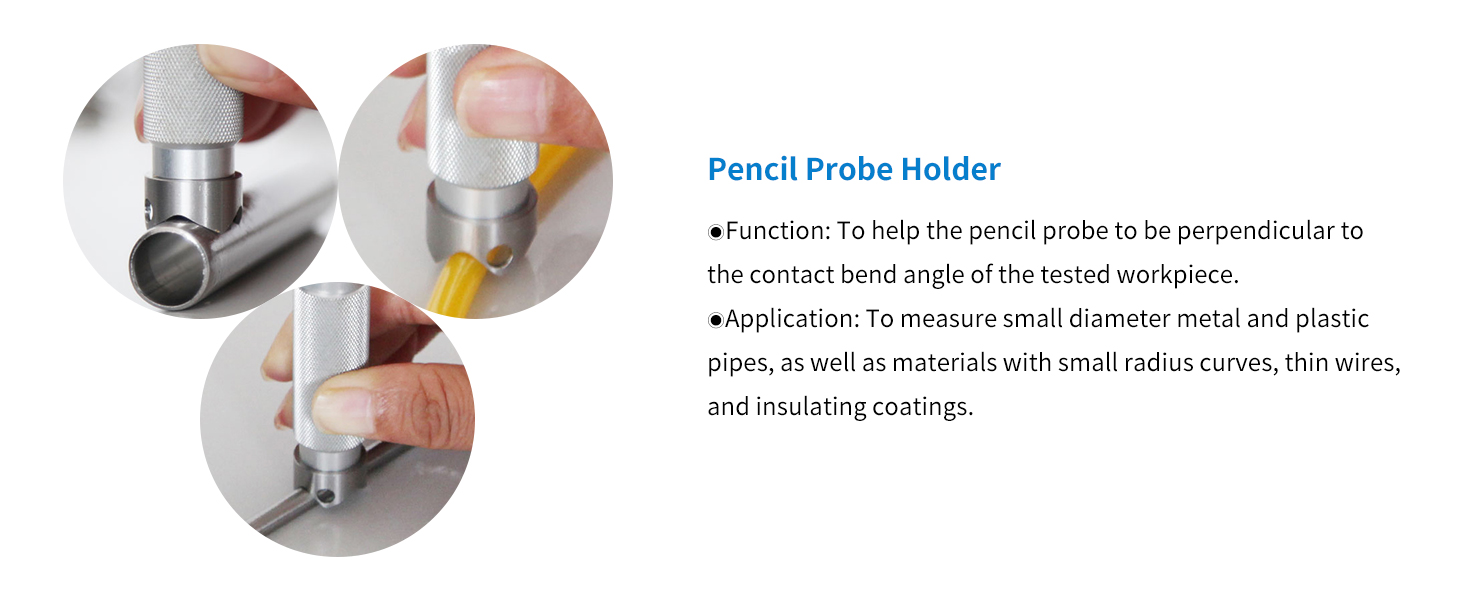

YUSHI Pencil Probe Holder

Function: To help the pencil probe to be perpendicular to the contact bend angle of the tested workpiece.

Application: To measure small diameter metal and plastic pipes, as well as materials with small radius curves, thin wires, and insulating coatings.

Testing Case 3: Double-Layer Material Measurement(Optional)

Double-Layer Measurement Option

It's for measuring and displaying the thickness of two layers of materials at the same time.

It includes multi-measurement and time-difference function.

Typical applications include double layer composites and coated metallic materials.

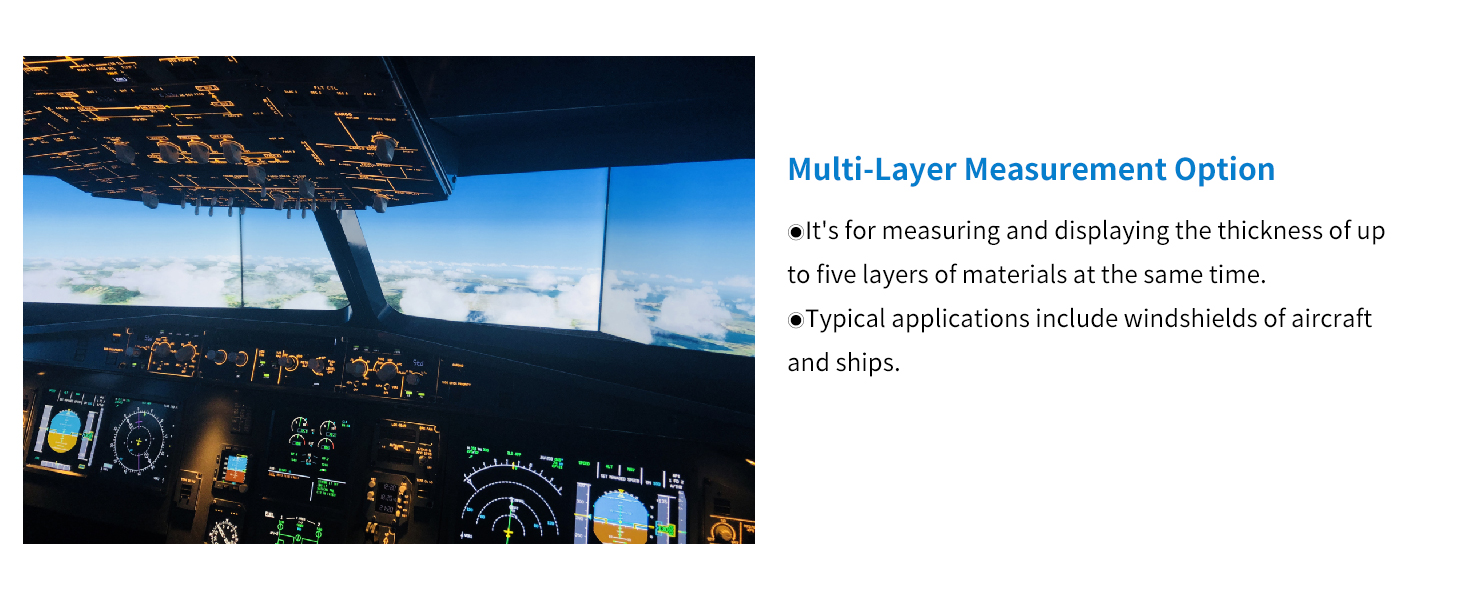

Testing Case 4: Multi-Layer Material Measurement(Optional)

Multi-Layer Measurement Option

Testing Case 5: Oxide Layer Measurement(Optional)

Internal oxide layer measurement option

Used to measure the thickness of the inner wall oxide layer of boiler pipe fittings

The instrument can display the thickness of the metal substrate and the thickness of the oxide layer at the same time.

Using the standard D15A probe, the measurement range of the oxide layer is 0.25mm~1.25mm.

Testing Case 6: Ultra-thick Material Measurement(Optional)

Large Measurement Range Option

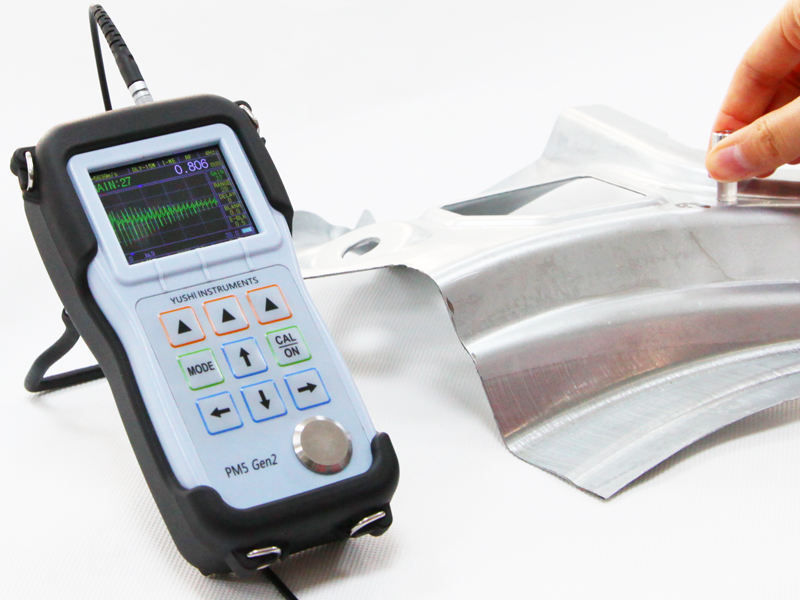

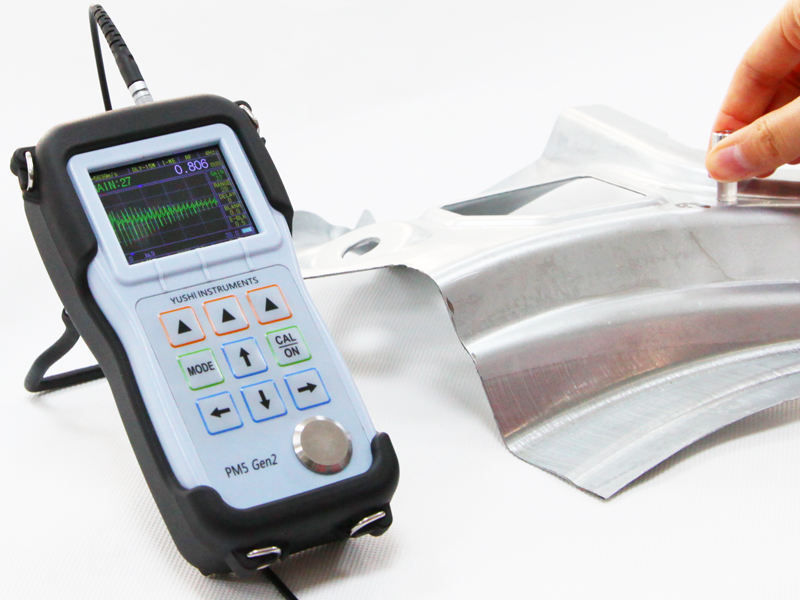

YUSHI PM5 GEN2 Ultrasonic Thickness Gauge

Precision Meets Performance

The YUSHI PM5 GEN2 is a high-performance ultrasonic thickness gauge designed for fast, accurate, and non-destructive measurement of material thickness. Whether you're inspecting metal, plastic, or coated surfaces, the PM5 GEN2 delivers reliable results — even on ultra-thin materials.

Key Features

High Accuracy: Measures as thin as 0.2 mm with 0.001 mm resolution

Through-Coating Measurement: No need to remove paint or coatings

Multiple Display Modes: Real-time A-Scan, B-Scan, and numeric readings

Auto & Multi-Echo Modes: Automatically selects the best mode for each material, with enhanced echo verification for consistent results

Visual Alarm: Alerts you when readings exceed preset thickness limits

USB Connectivity: Easily transfer data to PC using included software

Technical Specs

Display: 2.4" color OLED (320×240 resolution)

Measurement Range:

Interface-Echo (I-E): 1.5–27 mm

Echo-Echo (E-E): 0.2–13.5 mm

Multiple Verify Echo(I-ME): 0.2-9mm

Auto Mode: 0.2–27 mm

Units: mm / inch

Battery Life: 35+ hours (2 × AA batteries)

Dimensions: 153 × 76 × 37 mm

Weight: 280 g (with batteries)

Applications

Corrosion monitoring in pipelines and tanks

Quality control in manufacturing

Inspection of coated or painted metal surfaces

Structural evaluation in aerospace, marine, and construction

Ready to enhance your inspection process?

The YUSHI PM5 GEN2 offers unmatched accuracy, versatility, and ease of use — all in a compact, durable design.

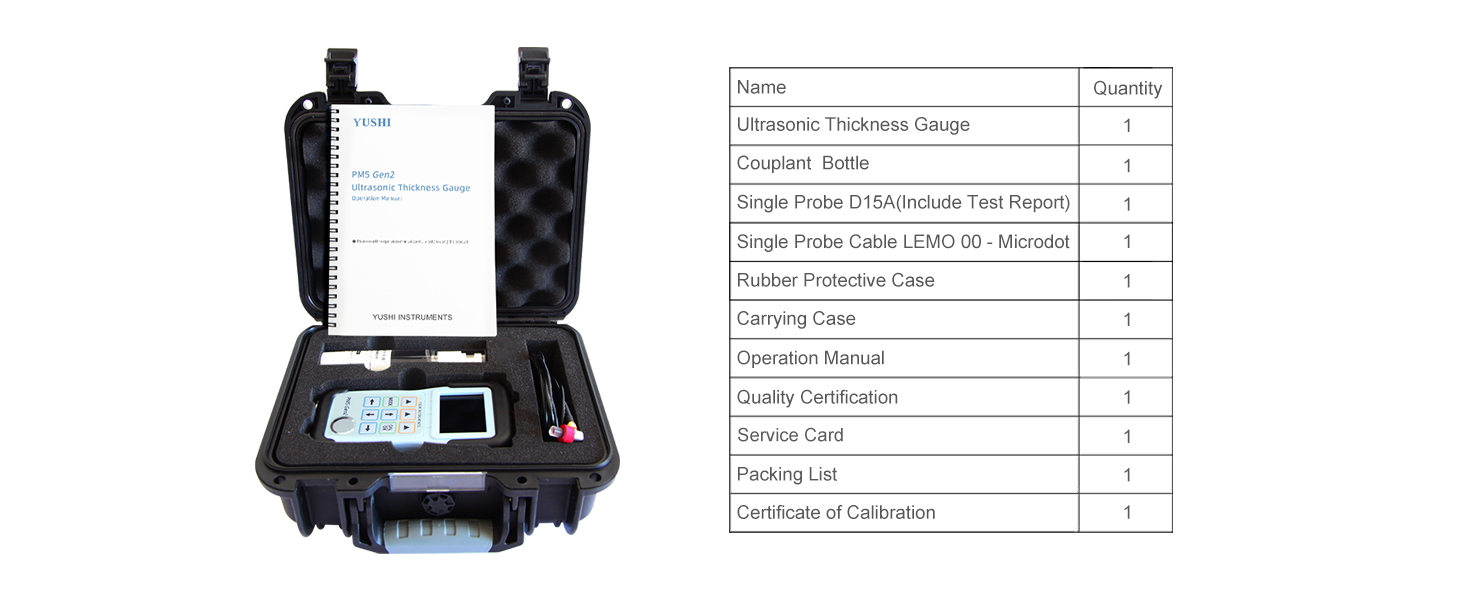

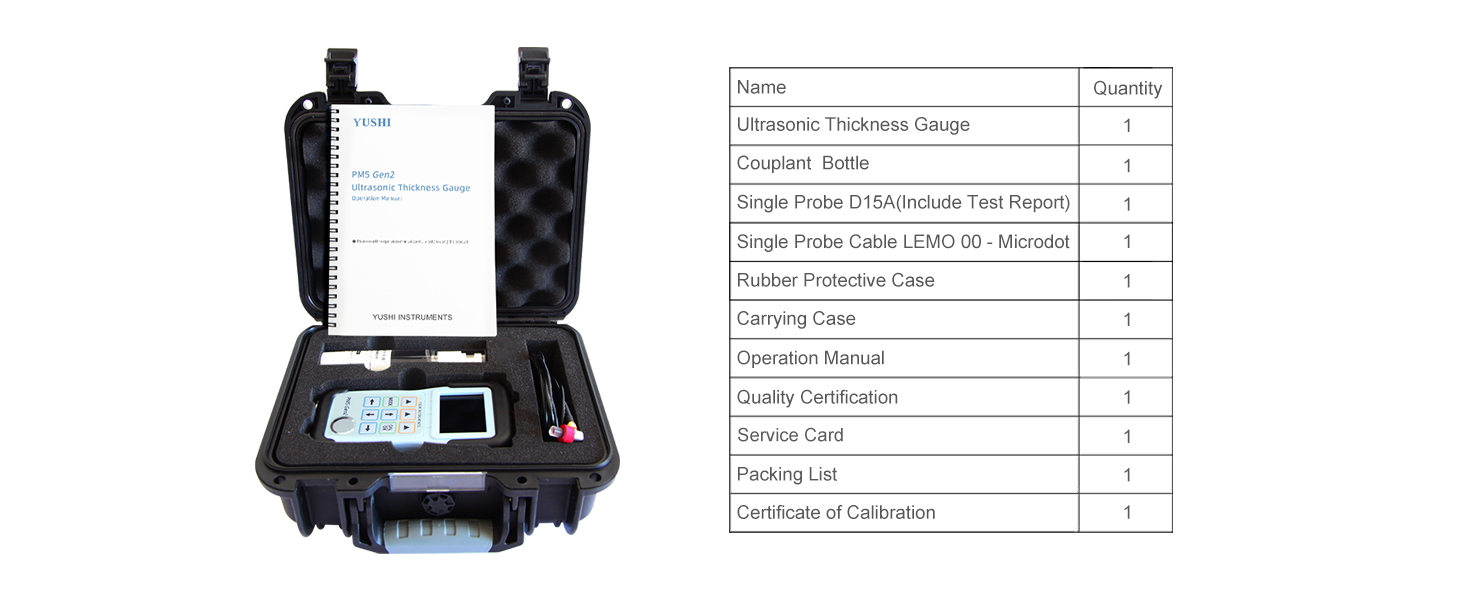

Packing List

Accessories

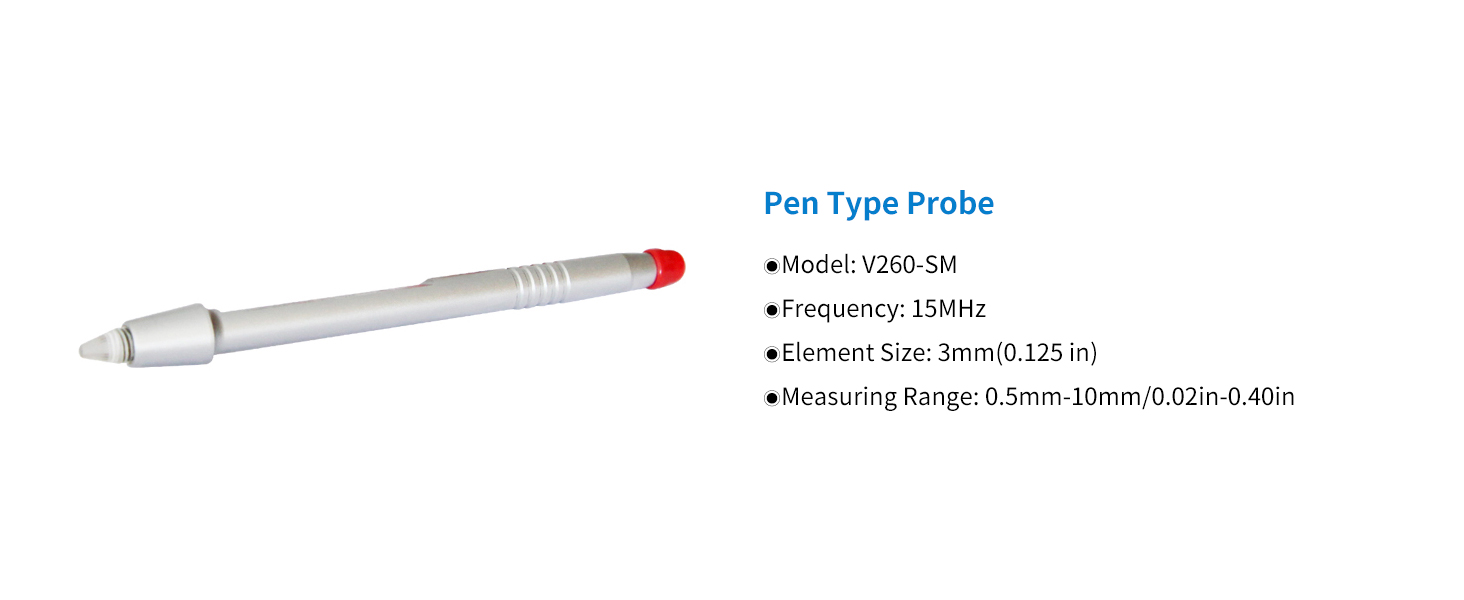

Probe Types

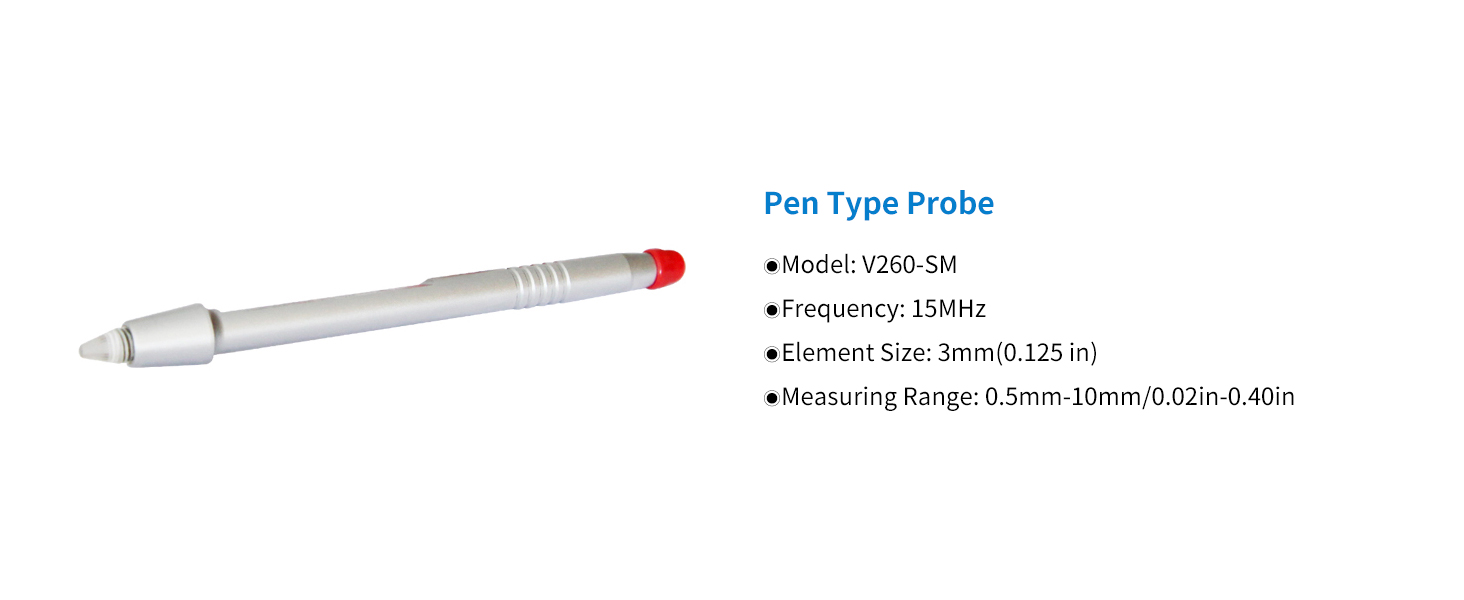

| Supply for Delay Line Probes, Contact Probes, Protective Film Probes, Pen Type Probes, Water Immersion Probes and High Temperature Probes |

| Calibration Methods | Zero Calibration, Calibrate Sound Velocity, One-Point Calibration, Two-Point Calibration, Set Sound Velocity, Material Sound Velocity Table |

| Thickness Range | 0.01 mm ~ 38 meters, depending on the materials, probe surface conditions, temperature and selected configuration/ 0.15mm~30mm(standard D15A probe, steel)

|

| Material Sound Velocity Range | 310 - 18699m/s The sound velocity can be calculated for objects with known thickness |

| Resolution (Optional) | Low Resolution:0.1mm / Standard Resolution:0.01mm/ High Resolution:0.001mm/ Ultra High Resolution (Optional) 0.0001mm or 0.1um(I-ME mode) |

| Probe Frequency Range | 0.5MHz~20 MHz |

| Measurement Units | mm, inch, micron, mils |

| Measurement Update Rate | 4Hz, 8Hz, 16Hz per second optional |

| Measuring Material | Most material measurements can be performed using single element transducers.

|

| Measuring Range | 0.01mm~38m, depends on materials, probe types and optional features. |

| TDG Function | The initial pulse or interface echo can be effectively reduced by reducing the initial gain, and the bottom echo of the measured sample can be increased by increasing the maximum gain, making measurement easier. |

| Measuring Mode | I-E,I-E-E,I-ME,AUTO,P-E,E-E,E-EV. |

| Resolution | Standard display resolution is 0.001mm.

|

| Multiple Measurement Units | mm, inch, μm, mil |

| High-Temperature Measurement | Temperature up to 500°C |

| Default System configuration | For user convenience, the default conditions of the probes used by the instrument have been set. |